The National Animal Supplement Council (NASC)

is a California-based nonprofit industry advocacy and educational group that is

dedicated to protecting and enhancing the health of companion animals (dogs,

cats, and horses) in the United States.

Founded in 2002, the NASC is made up of

more than 140 businesses that are committed to providing  high-quality health

supplements and nutritional supplements for these animals. Health supplements,

such as those that contain glucosamine, chondroitin sulfate,

methylsulfonylmethane (MSM), parsley (Petroselinum

crispum, Apiaceae), and peppermint (Mentha

× piperita, Lamiaceae), are

intended to support maintenance of normal biological structures and functions. Nutritional

supplements, such as those that contain vitamins and minerals, are intended to

provide nutritional value as a component of a complete and balanced diet.1,2 high-quality health

supplements and nutritional supplements for these animals. Health supplements,

such as those that contain glucosamine, chondroitin sulfate,

methylsulfonylmethane (MSM), parsley (Petroselinum

crispum, Apiaceae), and peppermint (Mentha

× piperita, Lamiaceae), are

intended to support maintenance of normal biological structures and functions. Nutritional

supplements, such as those that contain vitamins and minerals, are intended to

provide nutritional value as a component of a complete and balanced diet.1,2

NASC members are located around the world,

including in the United States, Canada, Europe, Australia, and China. An NASC

Primary Supplier Member must be a manufacturer, formulator, bottler, labeler,

or re-packer that markets its brand as the supplier of record. An NASC

Associate Member may be involved in selling or distributing animal

health/nutritional supplements as a distributor, dealer, retailer, veterinarian,

or internet/catalog company.

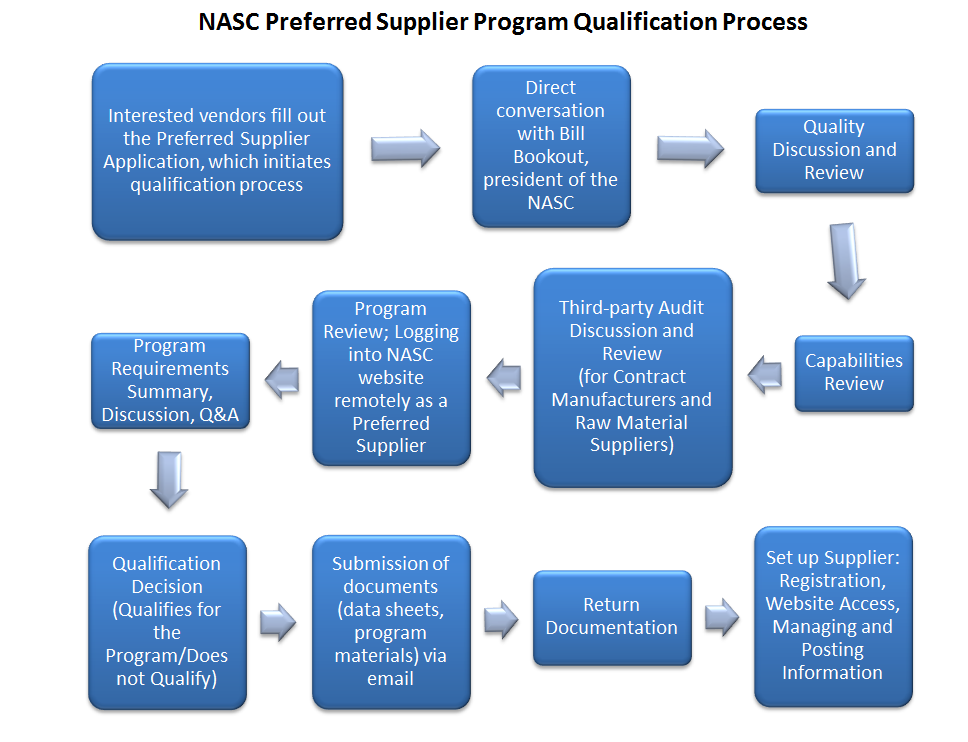

All NASC members are vetted in a direct

interview that presents and clarifies the requirements of the organization and

the standards to uphold. In addition, most NASC members complete an independent

NASC quality audit that, when passed, enables them to display the NASC

Quality Seal on their packaging and marketing materials. NASC membership demonstrates

a commitment to upholding specific quality standards, which the NASC hopes, in

turn, will increase consumer confidence in the animal  supplement industry.2 supplement industry.2

Preferred Supplier

Program Overview

The NASC Preferred Supplier Program is a

self-regulatory program that was initiated to help extend responsibility,

accountability, and uniformity upstream to the beginning of the animal

supplement supply chain. It also helps NASC members identify reputable suppliers

of reliable raw materials. “With the increased scrutiny on suppliers and supply

chain management, our intention has been, always, to keep our members ahead of

the regulatory curve,” said Bill Bookout, president of the NASC and chair of

its board of directors (oral communication, August 31, 2016).

Through data sharing, all involved parties

save time and money through the NASC’s Preferred Supplier Program. Suppliers

avoid having to submit to audits for every customer, and NASC members do not

have to go through the process of qualifying each supplier. Thus, all parties

contribute to the program and all parties benefit from the program, according

to Bookout.

The program qualifies suppliers in four

categories: Raw Material Suppliers, Contract Manufacturers (many NASC member

companies that market their own brand of products rely on one or more

third-party manufacturers to produce their products), Laboratories and

Research, and Service Providers (e.g., insurance providers, packagers or providers

of packaging components, legal service providers, web service providers, etc.).

So, in the context of the NASC’s program, the term “Preferred Supplier”

encompasses a wide variety of product and service providers along the supply

chain and is not limited only to suppliers of raw materials.3

There is an annual fee for each company in

the Preferred Supplier Program, and this covers the posting of all Preferred

Supplier information in the Members Section of the NASC’s website, the posting

of a company sales profile for all Preferred Suppliers, the opportunity to

conduct webinars and/or educational programs for NASC members, the availability

of contacts at NASC member companies, attendance at the Preferred Suppliers

Only Meeting during the NASC Annual Conference, and the opportunity to provide

input about the program.

Raw Material Suppliers and Contract

Manufacturers must complete and submit a Preferred Supplier Data Sheet, which

includes information about the manufacturing facility, testing information,

current Good  Manufacturing Practice (cGMP) compliance details, and more. In

addition, Raw Material Suppliers must complete and submit a Non-Botanical

Ingredient Data Sheet or a Botanical Ingredient Data Sheet for each unique ingredient

that the company supplies. Manufacturing Practice (cGMP) compliance details, and more. In

addition, Raw Material Suppliers must complete and submit a Non-Botanical

Ingredient Data Sheet or a Botanical Ingredient Data Sheet for each unique ingredient

that the company supplies.

These data sheets are modeled after the

data sheets of the Standardized Information on Dietary Ingredients (SIDI)

protocol, but have been adapted for the animal supplement industry. The SIDI

initiative is a voluntary, industry-wide protocol intended to standardize and

streamline communication of information about dietary ingredients from raw

material suppliers to finished product manufacturers. It is a cooperative

effort among three of the leading trade associations for the dietary supplement

industry: the Consumer Healthcare Products Association (CHPA), the Council for

Responsible Nutrition (CRN), and the United Natural Products Alliance (UNPA).4

For each ingredient that is qualified by

the NASC’s program, five batch/lot numbers (from one supplier) of that

ingredient must be tested to verify the information on the respective

certificate of analysis (COA) that accompanies each batch/lot. A COA is the

supplier’s test results for the batch/lot of raw material being supplied. The

information provided on the COA depends on the raw material, but it usually

includes information about quality, strength, purity, and composition. It may

also include notation of the plant part(s) used (for botanical ingredients), the

geographical source of the raw material, concentrations of marker compounds, and

levels of potential contaminants (if detected), including microbial (e.g., Salmonella and Escherichia coli) count and heavy metal (e.g., lead, mercury,

cadmium, and arsenic) count. In the case of boswellia (Boswellia spp., Burseraceae), for example, the COA could include

boswellic acid content. For garlic (Allium

sativum, Amaryllidaceae), it could include allicin yield. Methods of

analysis are also noted.

Samples from the first two batch/lot

numbers may be tested by the Raw Material Supplier from their own in-house laboratory

or submitted by the Raw Material Supplier for testing by an NASC-approved

laboratory. However, samples from the other three batch/lot numbers must be

submitted either by an NASC member that sources the ingredient from that

supplier, or by another customer of that supplier that uses the ingredient in

its product formulations, for testing by an independent, third-party, NASC-approved

analytical laboratory in the United States. The three independent tests, which

are conducted at the expense of the supplier, break the chain of custody and

eliminate sample bias. These tests may be performed by the laboratories that

are listed as Preferred Suppliers on the NASC’s website, in addition to other

reputable laboratories in the industry.

All raw materials must be tested using

methodology that follows current established recommendations of the United

States Pharmacopeia (USP), AOAC International, other recognized testing

authorities, published monographs (including monographs of the American Herbal

Pharmacopoeia [AHP]), or other published testing methods. Each raw material

qualified by the NASC’s program is subject to re-verification with one random

test performed annually.

Raw Material Suppliers must meet these

requirements for each individual ingredient in order for those ingredients to

be qualified by the NASC’s program, but there is no additional fee for qualifying

additional ingredients

For Contract Manufacturers and Raw Material

Suppliers, the NASC will recognize facility audits that have been conducted by

NSF International, the Safe Quality Food (SQF) Institute, Underwriters

Laboratories (UL), the Natural Products Association (NPA), and other auditing bodies

that are accredited to confirm that manufacturing facilities are operating in

accordance with dietary supplement cGMPs found in 21 CFR (Code of Federal

Regulations) Part 111, which is called “the cGMP rule.” The cGMP rule requires

“persons who manufacture,

package, label, or hold a dietary supplement to establish and follow current

good manufacturing practice(s) to ensure the quality of the dietary supplement

and to ensure that the dietary supplement is packaged and labeled as specified

in the master manufacturing record.”5

The NASC requires Contract Manufacturers and Raw Material Suppliers to have

a current audit certificate. Typically, these certificates expire every one or

two years. If a Contract Manufacturer has not been audited, the NASC can conduct

a facility audit, but this takes more time.

Laboratories seeking qualification by the NASC’s program must complete and

submit an Analytical Laboratory Data Sheet. These laboratories must comply with

Good Laboratory Practices (GLPs) and good analytical methodology (as

recommended by USP, AOAC International, etc.). In addition, Service Providers

must complete and submit a Service Provider Data Sheet.

The data sheets submitted by all of the Preferred Suppliers, along with the

required testing information and any additional documentation (e.g., kosher statement,

hormone statement, sterilization methods [irradiation, ethylene oxide]

statement, genetically modified organism statement, and organic certification statement, etc.) are available for NASC members to download on the NASC website. In

addition, Preferred Suppliers may choose to post liability insurance

certificates.

Preferred Suppliers, however, are not required to post confidential

information to the NASC website. This includes proprietary processes or

anything covered under trade secrets. Preferred Suppliers may choose to make

certain information available to the NASC under a non-disclosure agreement

(NDA). Additionally,  distributors are not required to disclose their suppliers,

since manufacturers could then cut them out and go directly to the supplier,

but distributors must be able to verify how their suppliers were qualified. distributors are not required to disclose their suppliers,

since manufacturers could then cut them out and go directly to the supplier,

but distributors must be able to verify how their suppliers were qualified.

Ingredients that have been qualified by the

program are searchable alphabetically by common name on the NASC website. Each common

name listing includes all of the Raw Material Suppliers that have been

qualified to supply that particular ingredient, in addition to the required

testing information and additional documentation.

Conclusion

Currently, more than 60 Preferred

Suppliers, some of which are also NASC members and most of which are located in

the United States, have been qualified by the NASC’s program. These Preferred

Suppliers are able to display the blue NASC Preferred Supplier Seal. “Our goal

with the program is not to get every single company that possibly participates

in this industry into the program,” said Bookout (oral communication, December

15, 2016). “Our goal is to get quality suppliers into the program, to

differentiate them from opportunistic suppliers, and to reduce the

ever-increasing cost of quality and qualifying suppliers.”

According to Bookout, the NASC’s program

has qualified most of the main ingredients commonly used in animal supplements

(see Table 1), such as glucosamine and chondroitin,* MSM,† and hyaluronic

acid.‡ However, the NASC hopes to start qualifying more herbal

ingredients (see Table 2) under the program soon.

According to data from the Chicago-based

market research firm SPINS, cross-channel aggregate** sales of animal

supplements totaled almost $110 million in the 52-week period that ended

November 27, 2016, an 11.2% increase in sales from the previous year. Table 1: Top-Selling Pet Supplements Overall

Primary Ingredient

| Sales

| % Change from Previous Year

| | Glucosamine | $21,244,413 | -6.1% | | Glucosamine/Chondroitin | $20,513,548

| 57.3% | | Vitamin E (not Ester-E) | $6,998,649

| 108.6% | | Multiple Vitamin (Adult) | $4,630,069

| -7.5% | | Animal Protein (Whey and Casein) | $3,934,666

| 127% | Parsley (Petroselinum crispum)

| $2,794,133

| -12.9% | | Zinc | $2,754,218

| 214.1% | | Animal and Plant Protein Combination | $2,544,139

| 19.5% | | Chlorophyll/Chlorella | $2,039,035

| -62.3% | Source: SPINS/Cross-channel aggregate** for the 52-week period ending November 27, 2017.

Table 2: Top-Selling Herbal Pet SupplementsPrimary Ingredient

| Sales

| % Change from Previous Year

| Parsley (Petroselinum crispum)

| $2,794,133

| -12.9% | | Chlorophyll/Chlorella | $2,039,035

| -62.3% | Mints (Mentha spp.)

| $1,831,908

| 38.2% | Pumpkin (Cucurbita pepo)

| $862,966

| 150.4% | Chamomile (Matricaria recutita)

| $465,978

| -32.6% | Flax Seed and/or Oil (Linum usitatissimum)

| $249,602

| 7.9% | Menthol (derived from Mentha species)

| $173,344

| -11% | Lavender (Lavandula angustifolia)

| $143,232

| -0.4% | Garlic (Allium sativum)

| $124,020

| -73.2% | Tea Tree Oil (Melaleuca alternifolia)

| $113,826

| 34.2% | Source: SPINS/Cross-channel aggregate** for the 52-week period ending November 27, 2017

The Preferred Supplier Program officially

began in 2014 and, in 2016, it grew significantly, according to Bookout. He

also said that the feedback the NASC has received about the program has all

been extremely positive.

Bookout said the NASC is also planning to

expand the program beyond dietary supplements for animals. “We are going to

expand the program out to pet food and pet treats manufacturers as well,” he

said.

The NASC’s Preferred Supplier Program was

put together with the help of NSF International auditors. “I have been told by

everyone who has looked at it that it will stand up to the independent scrutiny

of a third-party audit,” said Bookout. “At the end of the day, consumer

confidence is increased, and, in our case, the animals benefit.”

—Connor Yearsley

|

The

Regulatory Situation for the Animal Supplement Industry in the United States

The NASC was established to provide a

complete regulatory and compliance pathway for the animal supplement industry

because of the absence of a legal category for animal dietary supplements and

because of apparent efforts by regulatory bodies to remove many of these

products from the market.9

In 1994, the Dietary Supplement Health and

Education Act (DSHEA) was passed, and it classified dietary supplements as a

category of food under the Federal Food, Drug, and Cosmetic Act. This meant

that dietary ingredients could be used without premarket approval as long as

they were marketed in dietary supplements before October 15, 1994.9-11

However, DSHEA did not address animal

supplements, probably because that segment was very small at the time and

because the purpose of the legislation was to address the increasing demand for

human dietary supplements,9 as well as consumer and industry

concerns at the time about government regulations that would have limited

access to many supplements. In 1996, the Food and Drug Administration’s (FDA’s)

Center for Veterinary Medicine (CVM), which is primarily responsible for the

regulation of animal food and drugs, stated that DSHEA does not apply to animal

products, reasoning that ingredients with a history of safe use in human

dietary supplements may not necessarily be safe for animals. Different animal

species require different nutrients, they absorb and metabolize substances

differently, and they may exhibit different toxic reactions to substances.10

Therefore, products marketed as animal

dietary supplements, which typically fall under the category of “animal feed,”

are still subject to the pre-DSHEA regulatory environment and usually must be

made up of ingredients that are generally recognized as safe (GRAS), approved

as food additives, or listed in the Official

Publication of the Association of American Feed Control Officials.11

Animal supplements are not allowed to make

claims except about the nutrition, taste, and/or aroma of the product. In some

cases, the CVM allows claims of “nutritional support” of specific organs and/or

body functions. As with human dietary supplements, animal supplements that

claim to treat, mitigate, or prevent disease are considered unapproved new

drugs.11

The Food Safety Modernization Act (FSMA),

which was passed in 2011 and emphasizes preventing contamination in the food

chain instead of responding to it, established cGMPs for animal food

production. So, animal supplements marketed as food are subject to FSMA rules.12

|

* Glucosamine and chondroitin are compounds

derived from cartilage and are often used in combination to treat conditions

associated with osteoarthritis.6 † Methylsulfonylmethane

(MSM) is a natural compound found in some primitive plants (e.g., Equisetum arvense, Equisetaceae) and

other natural sources, and that can be prepared through oxidation of dimethyl

sulfoxide. It is used to treat a variety of conditions, such as arthritis,

joint inflammation, tendonitis, and musculoskeletal pain.7 ‡ Hyaluronic acid is a compound found in the

tissues and body fluids of vertebrates, and in some bacteria, that can help

with joint lubrication, water homeostasis, filtering effects, and regulation of

plasma protein distribution.8 ** Includes sales in the Natural Channel,

Specialty Gourmet Channel, and Conventional Channel. The SPINSscan Natural

Channel includes products sold at full-format natural product supermarkets,

small to mid-sized chains, and independent and cooperative stores across the

continental United States (excluding sales at Whole Foods Market). The SPINSscan Specialty Gourmet Channel includes products sold at full-format supermarkets with

more than $2 million in annual sales, with SPINS-defined specialty items making

up at least 25% of their overall volume. The SPINSscan Conventional Channel includes natural, organic,

specialty, and wellness products sold at conventional outlets in the United

States (data determined in collaboration with Information Resources Inc. [IRI

Worldwide]).

References

- Profile.

National Animal Supplement Council website. Available at: http://nasc.cc/profile/.

Accessed January 4, 2017.

- Frequently

Asked Questions. National Animal Supplement Council website. Available at: http://nasc.cc/faqs/.

Accessed January 4, 2017.

- NASC

Preferred Suppliers. National Animal Supplement Council website. Available at: http://nasc.cc/preferred-suppliers/.

Accessed January 4, 2017.

- Frequently

Asked Questions. SIDI Work Group website. Available at:

www.sidiworkgroup.com/FAQ. Accessed January 12, 2017.

- Guidance

for Industry: Current Good Manufacturing Practice in Manufacturing, Packaging,

Labeling, or Holding Operations for Dietary Supplements; Small Entity

Compliance Guide. Food and Drug Administration website. December 2010.

Available at: www.fda.gov/Food/GuidanceRegulation/GuidanceDocumentsRegulatoryInformation/DietarySupplements/ucm238182.htm.

Accessed January 4, 2017.

- Chondroitin.

University of Maryland Medical Center website. Available at: http://umm.edu/health/medical/altmed/supplement/chondroitin.

Accessed January 5, 2017.

- Methylsulfonylmethane

(MSM). Drugs.com website. Available at:

www.drugs.com/npp/methylsulfonylmethane-msm.html. Accessed January 12, 2017.

- Fraser

JRE, Laurent TC, Laurent UBG. Hyaluronan: its nature, distribution, functions,

and turnover. Journal of Internal

Medicine. 1997;242(1):27-33. doi: 10.1046/j.1365-2796.1997.00170.x.

- Regulation of Animal Health Supplements — A Historical Health Summary.

National Animal Supplement Council website. Available at: http://nasc.cc/historical-summary/.

Accessed January 6, 2017.

- Harrison

T, Jackson M. Pet Nutrition: A Legal Rundown. Nutraceuticals World website.

April 1, 2016. Available at:

www.nutraceuticalsworld.com/issues/2016-04/view_columns/pet-nutrition-a-legal-rundown.

Accessed January 6, 2017.

- DSHEA

Needed for Animal Supplements. Emord & Associates website. January 4, 2013.

Available at: http://emord.com/blawg/dshea-needed-for-animal-supplements/.

Accessed January 6, 2017.

- Final

Rule on Preventive Controls for Animal Food. Food and Drug Administration

website. Available at:

www.fda.gov/downloads/Food/GuidanceRegulation/FSMA/UCM461884.pdf. Accessed

January 6, 2017.

|